How Shape-Engineered EPE Foam Profiles Solve Packaging Challenges in Fragile Product Transport

When it comes to protective packaging, one size rarely fits all—especially in industries where products are fragile, irregularly shaped, or high in value. This is where shape-engineered EPE foam profiles show their true potential. By designing profiles specifically in L-shaped, U-shaped, round, or ring-shaped forms, manufacturers and suppliers can provide targeted protection that standard flat or sheet materials simply can’t achieve. These profiles aren't just padding—they are functional components that directly influence the safety and efficiency of product transport.

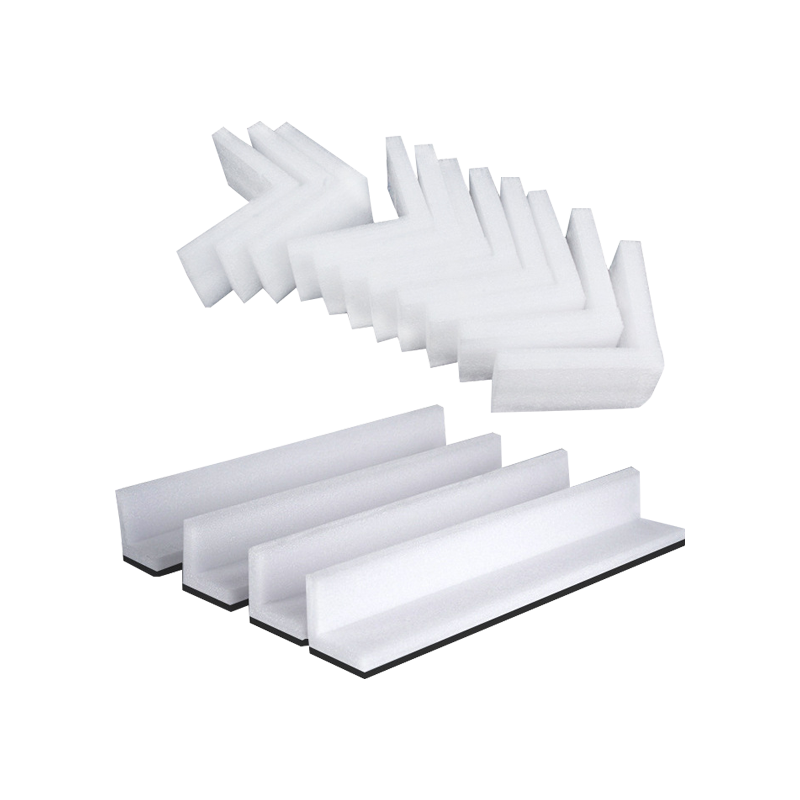

Each shape serves a very particular role in reducing the risk of damage. U-shaped profiles, for instance, are ideal for encasing edges of glass panels, mirrors, or screens, providing three-sided protection while staying lightweight and easy to handle. L-shaped designs protect corners—often the most impact-prone areas during loading and unloading. Meanwhile, ring-shaped EPE foam profiles are perfect for cylindrical objects like pipes, tubes, and delicate machine components, allowing them to be stacked securely without abrasion or slippage.

What makes these shapes so effective isn't just their geometry, but how they interact with the forces encountered in transit. Vibrations, shocks, and compression loads affect different parts of a product differently. By tailoring the foam shape to the product's weak points, packaging engineers can design protection where it’s needed most—reducing material waste while enhancing safety. For high-volume exporters or OEMs, this design-focused thinking results in fewer returns, lower claims, and better client satisfaction. It’s a technical advantage that also makes business sense.

Durability is another reason why EPE foam profile shapes are so widely used in protective packaging. Expanded polyethylene has a closed-cell structure that gives it excellent recovery properties—it compresses under pressure but returns to its original shape, making it reusable and ideal for repeated transport cycles. That’s especially beneficial in B2B supply chains where components are shuttled between factories, assembly lines, or end clients. Choosing the right profile shape ensures that this reusability doesn't come at the expense of product safety.

Even within a single shape category, customization adds a layer of precision. The thickness, internal groove size, density, and even color of each EPE foam profile can be adapted to match product requirements or branding needs. A large lighting fixture may need a wide, deep U-profile, while a smaller electronic module might use a narrow L-profile with anti-static treatment. By offering these customizations in-house, we ensure quicker production and better compatibility with our clients’ packaging lines, often eliminating the need for secondary adjustments during packing.

From a production standpoint, shape engineering involves tooling accuracy, temperature control during extrusion, and clean cutting edges—all of which contribute to consistent quality. Our technical team ensures that each batch of profiles, regardless of shape, meets tight tolerances to fit your products snugly. This minimizes product movement inside the package, which is one of the leading causes of transport damage. As a manufacturer with years of experience, we treat packaging as a precision task, not just a wrapping solution.

prevNo previous article

nextHow Custom EPE Foam Profiles Deliver Superior Protection and Efficiency in B2B Packaging

English

English 中文简体

中文简体 Español

Español